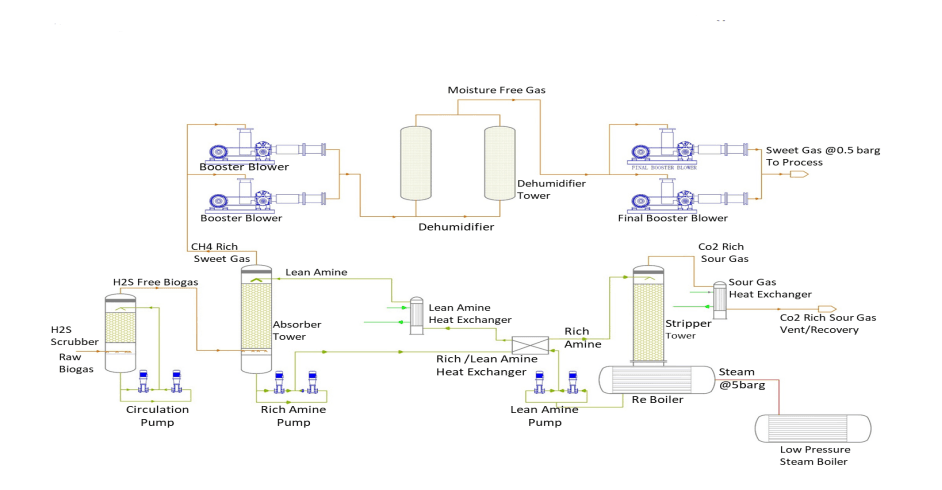

Biogas Purification By Amine Scrubbing Technology

Our Amine Scrubbing CO₂ Purification Unit is designed to remove carbon dioxide (CO₂) from biogas through an absorption process using an amine solution. The CO₂ is selectively absorbed by the amine solvent, producing a purified methane stream.

Key Stages:

1. Gas Pressurization

2. CO₂ Removal (MEA Absorption)

3. Dehumidification

4. Methane Drying and Compression

5. CO₂ Stripping

6. CO₂ Venting

7. MEA Solution Cooling and Reuse

8. Heat Recovery

Carbon Dioxide (CO₂) Removal Process in Biogas Purification By Amine Scrubbing Technology